Crane Outrigger Pads: Essential for Safety and Stability

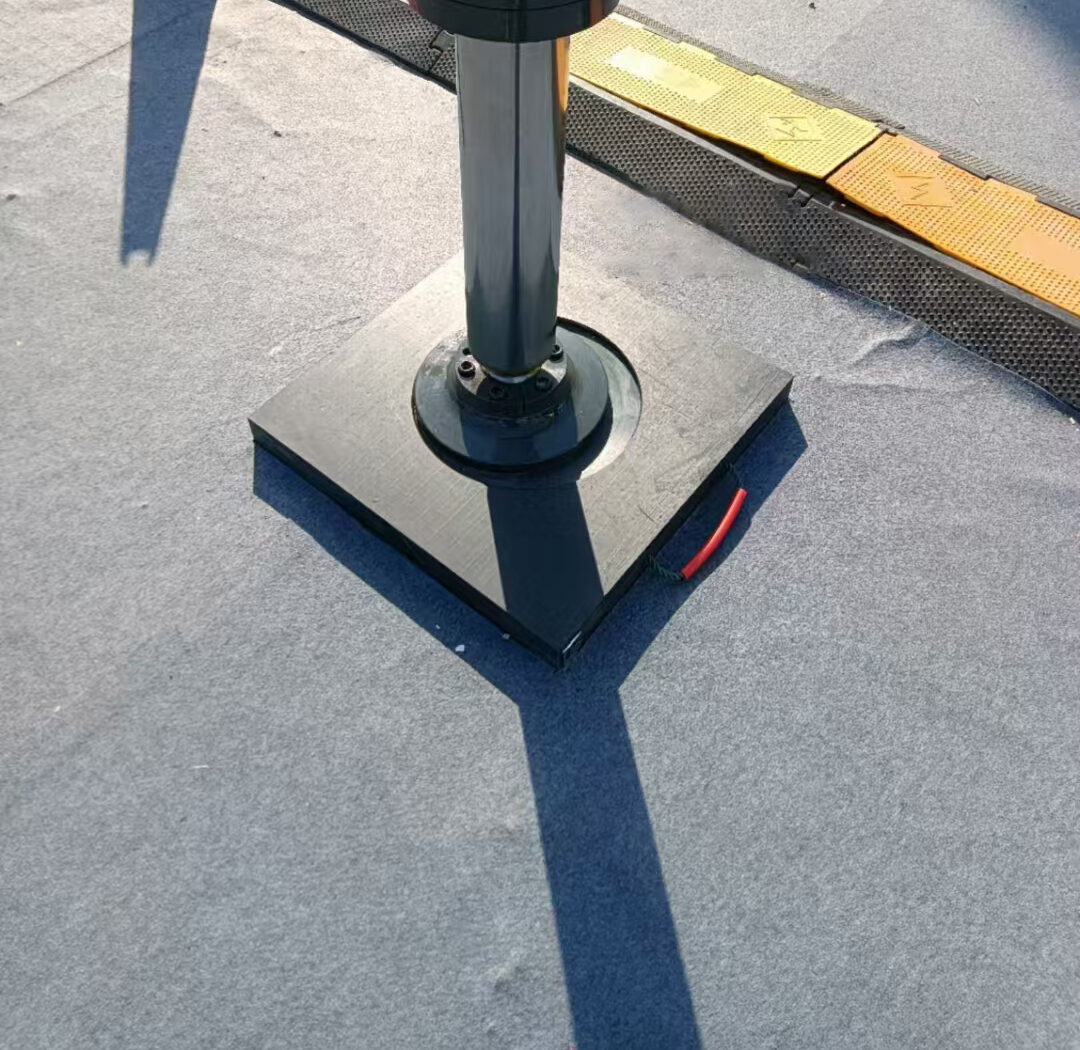

Outrigger Pads are crucial equipment for cranes and heavy machinery, designed to enhance stability and safety during operations. These pads evenly distribute the weight of the crane, ensuring a stable base and protecting sensitive surfaces from damage. Our high-quality outrigger pads are engineered to withstand the toughest conditions, offering durability, strength, and reliability.

Enhance Your Construction and Industrial Safety with High-Quality Crane Outrigger Pads

At Mat Hub, we specialize in manufacturing premium Crane Outrigger Pads designed for distributing the weight of cranes and heavy machinery, ensuring a stable and secure base for operations. With their high strength and durability, our outrigger pads are essential for preventing damage to surfaces, minimizing risks of tipping, and optimizing safety across construction and industrial sites.

Key Features of Our Crane Outrigger Pads

Superior Load Distribution

Engineered to evenly distribute the weight of heavy equipment, ensuring stability and reducing the risk of ground damage.

High Strength & Durability

Made from high-density materials to withstand extreme conditions and heavy loads, ensuring a long service life in demanding environments.

Protection for Sensitive Surfaces

Prevent damage to asphalt, concrete, grass, and other sensitive surfaces with our high-performance outrigger pads.

Easy Handling & Versatility

Lightweight and designed for easy handling, our crane outrigger pads can be used in a variety of terrains and industries.

Why Choose Mat Hub for Crane Outrigger Pads?

- Custom Sizes & Branding: Available in multiple sizes with logo branding options to suit your project needs.

- Built for Performance: Our outrigger pads are rigorously tested to ensure they provide unmatched stability and performance in any condition.

- Global Shipping: With efficient production and fast shipping capabilities, we deliver worldwide to keep your projects on schedule.

- Trusted by Industry Leaders: Our crane outrigger pads are used in a variety of industries, from construction to heavy lifting, trusted by professionals for their quality and reliability.

Applications of Crane Outrigger Pads

- Construction: Used in temporary roadways, crane stabilizing, and heavy lifting tasks.

- Industrial: Ideal for industrial machines, oil rigs, and infrastructure projects.

- Heavy Equipment: Perfect for lifting operations, truck-mounted cranes, and mobile cranes.

- Event Planning: Provides a stable foundation for large equipment in temporary event setups.

Need reliable, durable, and cost-effective Crane Outrigger Pads? Choose Mat Hub’s high-performance pads for your next project, and ensure safety and stability under any load.

Crane Outrigger Pads Specifications

Mat Hub crane outrigger pads are engineered to provide superior ground stability and weight distribution during crane operations. Made from high-performance materials, our outrigger pads are designed to prevent ground damage, enhance safety, and improve the overall efficiency of your crane operations.

Specifications

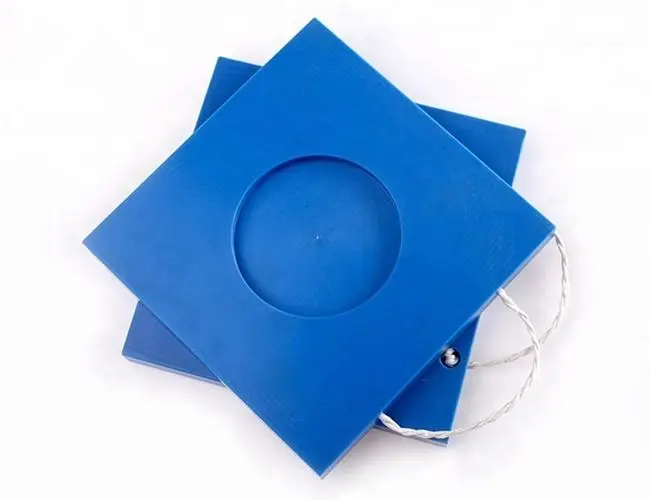

- Material: High-quality polyethylene (PE) or UHMWPE for maximum strength and durability.

- Thickness Range: 20mm to 150mm (custom thicknesses available upon request).

- Standard Sizes: 600mm x 600mm, 900mm x 900mm, 1200mm x 1200mm, or custom dimensions.

- Weight Capacity: Capable of handling crane loads up to 100 tons (depending on pad size and thickness).

- Temperature Resistance: Functional in temperatures ranging from -40°C to +80°C.

- Surface Finish: Textured or smooth options for enhanced grip and stability.

- Colors: Standard colors include black, but custom colors are available upon request.

- Certifications: ISO 9001, CE certified, and available with specific load testing certificates on request.

Crane Outrigger Pads Applications

Construction Sites

- Provides stable ground support for cranes and lifting equipment on construction sites.

- Prevents ground damage, reducing the need for costly repairs.

Heavy Equipment Operations

- Ensures safe and stable operations for cranes in challenging environments.

- Distributes the weight evenly across the ground, preventing sinkage or instability.

Outdoor Events & Temporary Sites

- Provides essential support for cranes and lifting equipment used in outdoor events.

- Prevents damage to lawns, pavement, and other delicate surfaces.

Emergency Operations

- Supports cranes and lifting equipment during emergency recovery or disaster response operations.

- Helps to prevent equipment instability when working on soft or uneven ground.

Mat Hub crane outrigger pads are designed to provide the highest level of stability, safety, and performance. Whether you’re working on a construction site, operating heavy machinery, or managing outdoor events, our pads ensure optimal support and protection for your crane operations.

Advantages of Mat Hub’s Crane Outrigger Pads

Discover why Mat Hub’s crane outrigger pads are a top choice for enhancing safety, preventing ground damage, and improving stability during crane operations.

1. Superior Load Distribution

Mat Hub’s outrigger pads are engineered to evenly distribute the crane’s load across a larger surface area, reducing the risk of ground sinkage and enhancing overall stability.

- Prevents Ground Damage: Reduces the risk of ground deformation, even in soft or unstable soil.

- Maximizes Stability: Enhances crane stability during heavy lifting and operation.

- Improves Safety: Reduces the risk of equipment tipping or sinking during use.

2. Heavy Duty and Durable

Our crane outrigger pads are built from high-quality materials like UHMWPE and HDPE, making them resistant to wear, impact, and extreme environmental conditions, ensuring long-term use.

- Long-lasting Durability: Made from tough, impact-resistant materials for long-term performance.

- Impact Resistant: Withstands heavy loads and harsh operating conditions without damage.

- Resistant to Wear: Designed to handle high-stress environments and reduce frequent replacements.

3. Lightweight and Easy to Handle

Despite their strength and durability, our outrigger pads are lightweight, making them easy to transport, handle, and install on-site, reducing labor and handling costs.

- Effortless Handling: Easy to carry and position, reducing worker strain.

- Reduced Transportation Costs: Lightweight design lowers shipping expenses.

- Quick Installation: Saves time during setup and teardown on job sites.

4. UV and Weather Resistant

Our outrigger pads are designed to withstand extreme weather conditions, including UV exposure, rain, and high/low temperatures, ensuring their performance in outdoor environments.

- UV Protection: Prevents degradation from prolonged sun exposure.

- Weatherproof: Withstands moisture, extreme temperatures, and environmental wear.

- Long-Term Outdoor Use: Ideal for cranes working in harsh outdoor conditions.

5. Environmentally Friendly Option

Mat Hub’s crane outrigger pads are made from recyclable materials, offering an eco-conscious solution for industries focused on sustainability.

- Recyclable Materials: Reduces environmental impact by enabling easy recycling after use.

- Non-Toxic: Made without harmful chemicals, ensuring a safe and sustainable option for your operations.

- Eco-Friendly Manufacturing: Produced with environmentally-conscious methods.

Crane Outrigger Pads Loading Capacity

Discover the loading capacities of Mat Hub’s crane outrigger pads, designed to support various cranes and heavy machinery in different operational environments. Choose the right pad based on your crane’s weight, operational load, and application needs.

| Pad Size (inches) | Material | Typical Load Capacity (Tons) | Thickness | Applications |

|---|---|---|---|---|

| 24″ x 24″ | UHMWPE, HDPE | 20 – 30 tons | 1″ – 2″ | Small cranes, light machinery |

| 36″ x 36″ | UHMWPE, HDPE | 50 – 75 tons | 1.5″ – 3″ | Medium cranes, construction equipment |

| 48″ x 48″ | UHMWPE, HDPE | 100 – 150 tons | 2″ – 4″ | Large cranes, heavy lifting operations |

| 60″ x 60″ | UHMWPE, Reinforced | 150 – 200 tons | 3″ – 5″ | Heavy-duty cranes, offshore projects |

| 72″ x 72″ | UHMWPE, Reinforced | 200 – 250 tons | 4″ – 6″ | Extra-large cranes, offshore platforms |

Key Factors Affecting Load Capacity

The load capacity of crane outrigger pads is influenced by several key factors, including material strength, pad size, thickness, and design. Choosing the right outrigger pad is crucial to ensure safety and efficient operations.

- Material Strength: UHMWPE and HDPE are high-strength materials that provide excellent load-bearing capacity and resistance to impact.

- Pad Thickness: The thicker the pad, the higher the load capacity. Thicker pads distribute weight more effectively, preventing the pad from sinking under heavy load.

- Pad Size: Larger pads increase surface area and weight distribution, ensuring stability for larger cranes and heavier loads.

- Reinforced Design: Reinforced outrigger pads are ideal for extreme-duty applications, offering increased load capacity for heavy machinery and offshore operations.

Example: 48″ x 48″ UHMWPE Crane Outrigger Pad

This size of crane outrigger pad can support up to **150 tons**, making it ideal for large cranes used in construction or heavy lifting. It is designed to withstand high stress and provide stable ground support, reducing the risk of sinking or failure during operations.

Crane Outrigger Pads Applications

Crane outrigger pads are essential components in ensuring the safe and efficient operation of cranes and other heavy machinery. They distribute the weight of the crane, providing stability and reducing the risk of ground damage. Here are some of the most common applications and benefits of using crane outrigger pads:

1. Construction Sites

- Stabilizing Cranes: Crane outrigger pads distribute the load of the crane, providing stability on uneven or soft ground.

- Preventing Ground Damage: Protects lawns, driveways, and other sensitive surfaces from being damaged by the weight of the crane.

- Safety Enhancement: Reduces the risk of accidents by ensuring cranes are securely positioned.

2. Oil and Gas Fields

- Heavy Load Distribution: Crane outrigger pads are designed to support heavy machinery used in oil extraction and drilling operations.

- Access to Remote Areas: Helps to stabilize cranes on challenging terrain, such as uneven soil or rocky surfaces.

- Preventing Environmental Impact: Minimizes ground disturbance, making it ideal for sensitive or protected environments.

3. Mining Operations

- Mining Equipment Stability: Ensures that cranes and other heavy lifting equipment are stable on uneven and often unstable mining terrain.

- Maximized Efficiency: Reduces the need for frequent adjustments and repositioning of cranes in mining sites.

- Protection from Soil Compaction: Minimizes the impact on the ground by distributing the weight of the machinery evenly.

4. Wind Farm Installations

- Crane Load Distribution: Helps cranes stabilize while installing wind turbines, particularly on challenging terrain.

- Ensuring Safe Lifting: Reduces the risk of cranes tipping over during the heavy lifting required for wind farm installations.

- Ground Protection: Prevents the soil and surrounding environment from being damaged during the installation process.

5. Infrastructure Projects

- Supporting Heavy Lifting: Crane outrigger pads ensure heavy lifting operations are conducted safely in infrastructure projects like bridges and roads.

- Protecting Ground Surfaces: Protects pavement and turf from the immense pressure generated by crane outrigger pads.

- Stabilization in Urban Areas: Helps cranes operate safely in urban construction sites with limited space.

6. Industrial Sites

- Heavy Machinery Support: Provides stability for cranes used in heavy-duty industrial lifting tasks.

- Protecting Sensitive Grounds: Safeguards floors and sensitive surfaces inside factories and warehouses.

- Ensuring Safety in Tight Spaces: Allows for the safe operation of cranes in confined industrial environments.

Whether for construction, mining, oil extraction, or wind farm installations, crane outrigger pads provide unmatched stability and safety. Contact us today to discuss how our crane outrigger pads can improve your operations and protect your equipment.

Get a Quote for Crane Outrigger Pads

Have questions or need a custom solution for your project? Contact us today for a personalized quote.

Our team is ready to provide high-quality products tailored to your needs.

Get a Quote for Crane Outrigger Pads

Have questions or need a custom solution for your project? Contact us today for a personalized quote. Our team is ready to provide high-quality products tailored to your needs.

1. What are crane outrigger pads and why are they important?

1. What are crane outrigger pads and why are they important?

PE500 sheets are made of **high-density polyethylene (HDPE)**, specifically designed to offer superior impact resistance, high wear resistance, and excellent chemical stability. These sheets are ideal for heavy-duty applications and environments requiring high-performance materials.

2. What materials are crane outrigger pads made from?

2. What materials are crane outrigger pads made from?

Some of the key features of PE500 sheets include:

- High wear resistance

- Excellent chemical resistance

- Low friction properties

- Non-toxic and safe for food applications

- Lightweight and easy to fabricate

- Good impact resistance, especially at low temperatures

3. How do I choose the right size of outrigger pad for my crane?

3. How do I choose the right size of outrigger pad for my crane?

PE500 sheets are widely used in various industries. Some of the most common applications include:

- Wear-resistant liners for machinery

- Conveyor parts and rollers

- Food processing applications (e.g., cutting boards, storage containers)

- Protective barriers for transportation

- Marine applications like dock fender pads and boat liners

- Environmental applications like geomembranes for landfills

4. Can crane outrigger pads be used on soft ground?

4. Can crane outrigger pads be used on soft ground?

PE500 sheets are highly durable and can withstand a wide range of demanding applications. They have excellent impact resistance, even at lower temperatures, and are resistant to abrasion, making them ideal for use in harsh environments. Depending on the application, PE500 sheets can last for many years, significantly reducing the need for maintenance or replacement.

5. How do I maintain and clean crane outrigger pads?

5. How do I maintain and clean crane outrigger pads?

Yes, PE500 sheets can be customized according to your specific requirements. We can offer various sizes, thicknesses, and colors to suit your project needs. Additionally, custom machining, cutting, and fabricating services are available for more specialized applications.

6. What weight capacity do crane outrigger pads have?

6. What weight capacity do crane outrigger pads have?

PE500 sheets require minimal maintenance. To keep them in good condition, simply clean the surface regularly using mild soap and water. Avoid using harsh chemicals or abrasives that could damage the material. For specific applications, ensure the sheets are stored properly to avoid excessive exposure to extreme temperatures or UV rays.

7. Can I use crane outrigger pads on uneven surfaces?

7. Can I use crane outrigger pads on uneven surfaces?

Compared to other materials, PE500 offers:

- Higher wear and impact resistance than standard HDPE

- Better chemical resistance, especially in industrial applications

- Lower friction properties, making it ideal for moving parts and conveyor systems

- Lightweight and easy to machine, reducing overall production costs

- Longer lifespan, reducing the need for frequent replacements

Frequently Asked Questions

Can’t find the answer? Reach out to our customer support team.

Our Factory

At Mat Hub, our advanced factory in China is equipped with 10 production lines, enabling us to efficiently produce high-quality ground protection mats, HDPE sheets, UHMWPE sheets, outrigger pads, and custom plastic parts. We prioritize precision and quality control at every step, ensuring products meet the highest standards. With a focus on quick delivery and customizable solutions, we are committed to providing reliable products for our global B2B clients.

Ready to safeguard your surfaces and power your projects? Let’s lay the foundation with Mat Hub today!

If you have any questions or require assistance about our ground protection mat, please do not hesitate to contact us. Our team is committed to delivering exceptional service and support to meet your needs promptly and professionally.

Get in Touch with Us

Fill out the form, and our team will get back to you within 24 hours.